ABOUT US

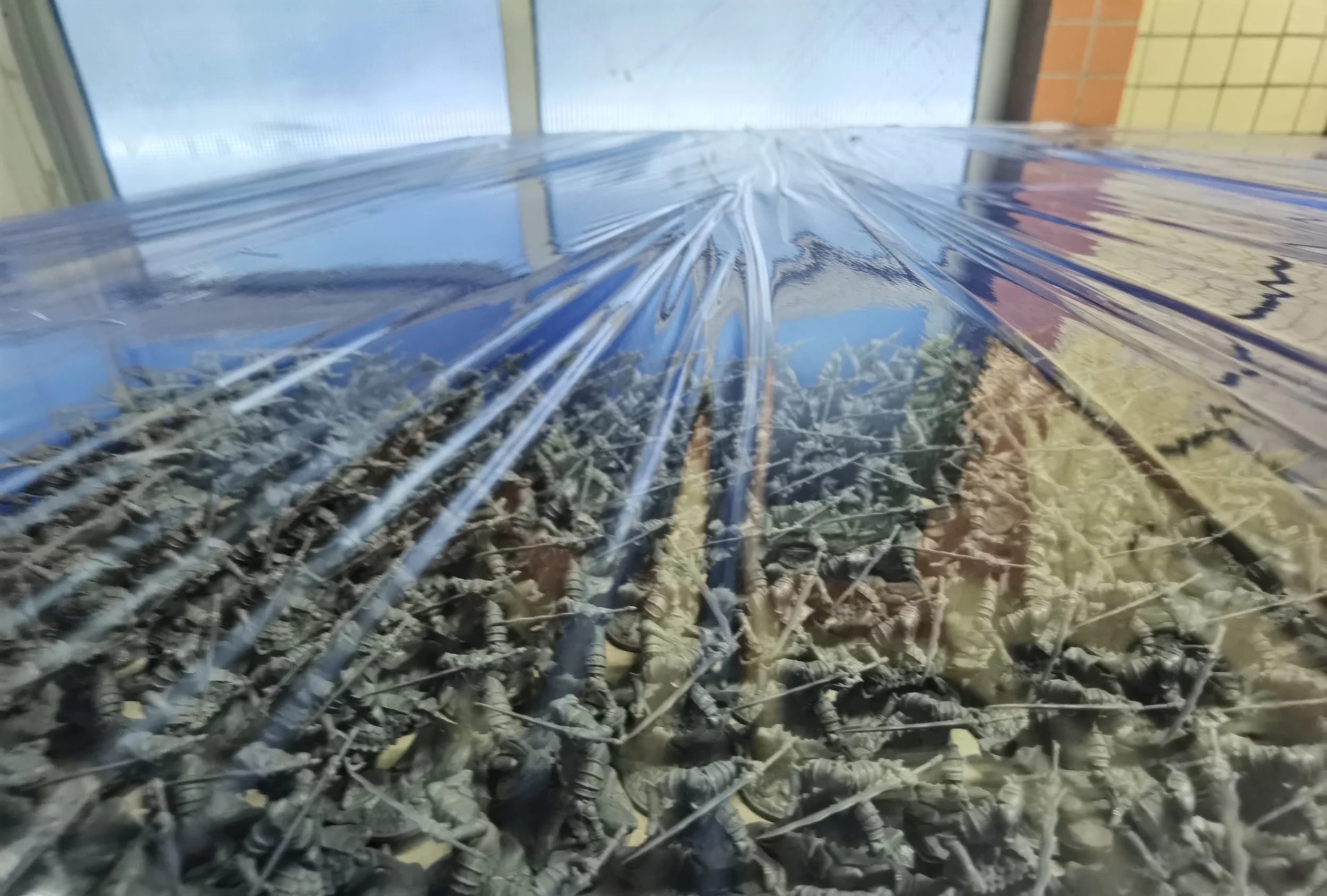

Assembly

*

PROJECT MANAGEMENT

*

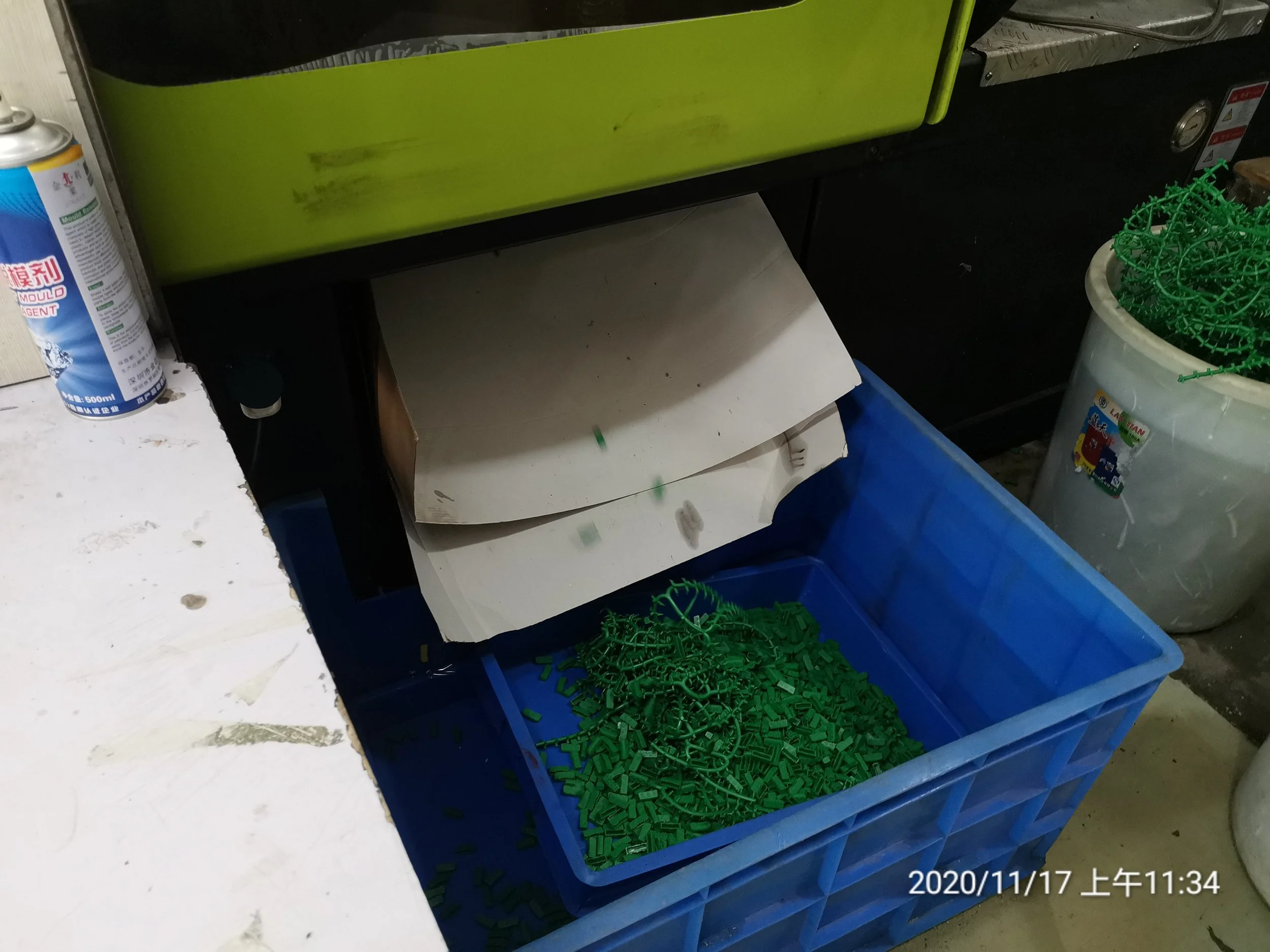

INJECTION

*

PACKING

*

PAD PRINTING

*

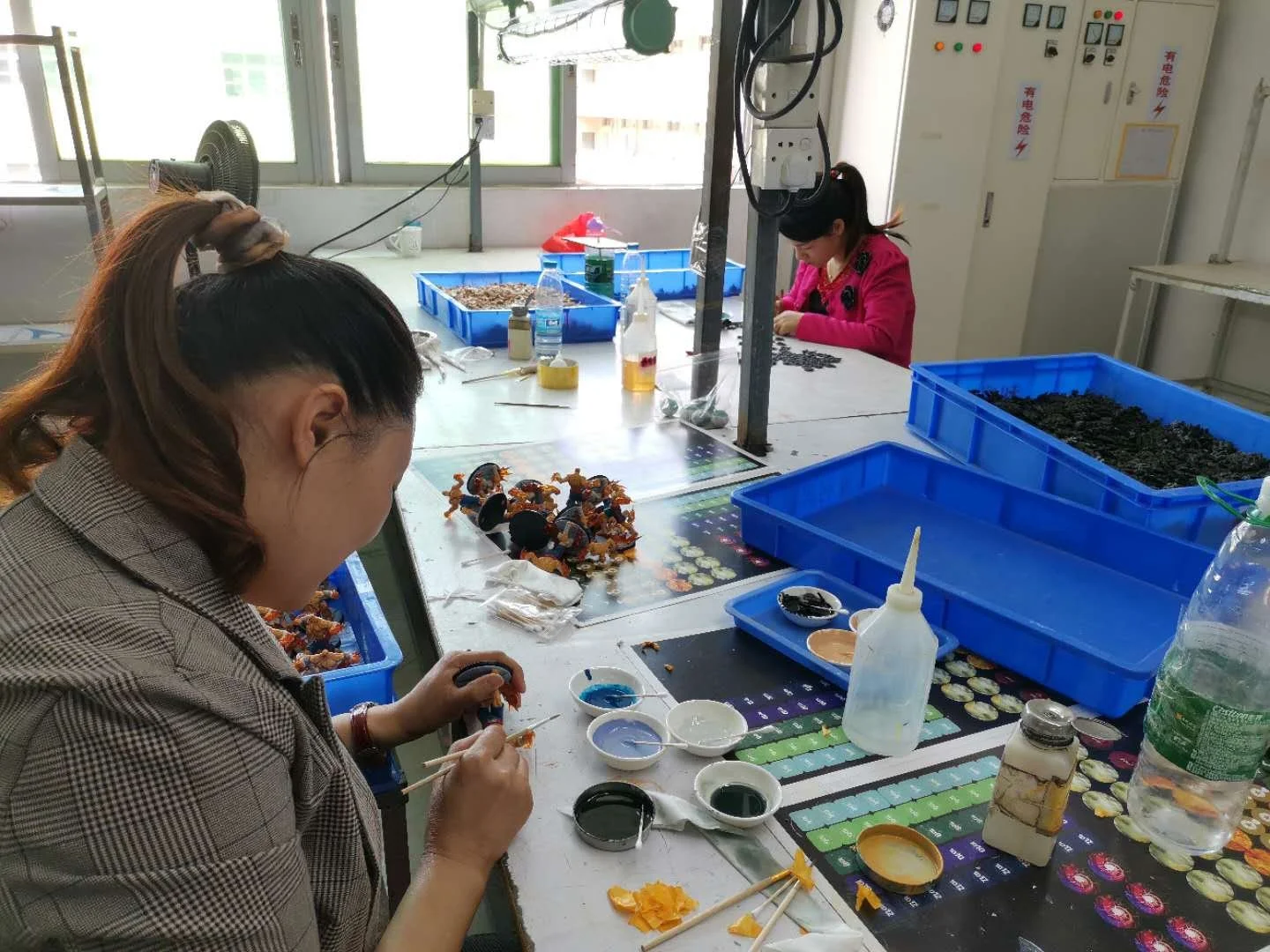

PAINTING

*

SHIPPING

*

SHIPPING PLANS

*

TOOLING

*

Assembly * PROJECT MANAGEMENT * INJECTION * PACKING * PAD PRINTING * PAINTING * SHIPPING * SHIPPING PLANS * TOOLING *

over 27 years of EXPERIENCE

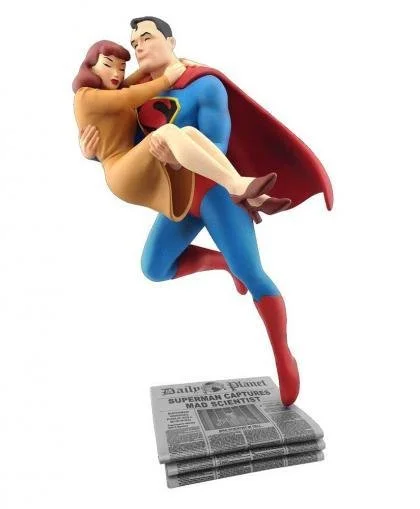

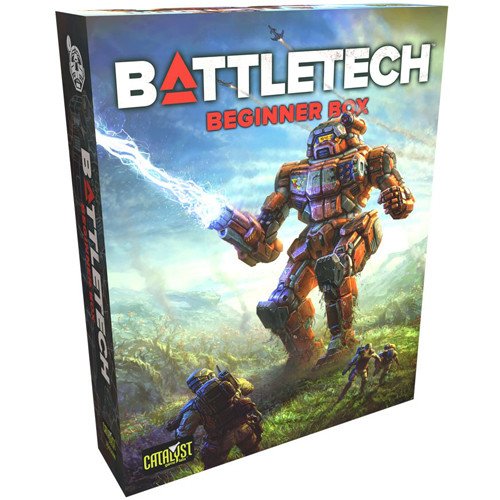

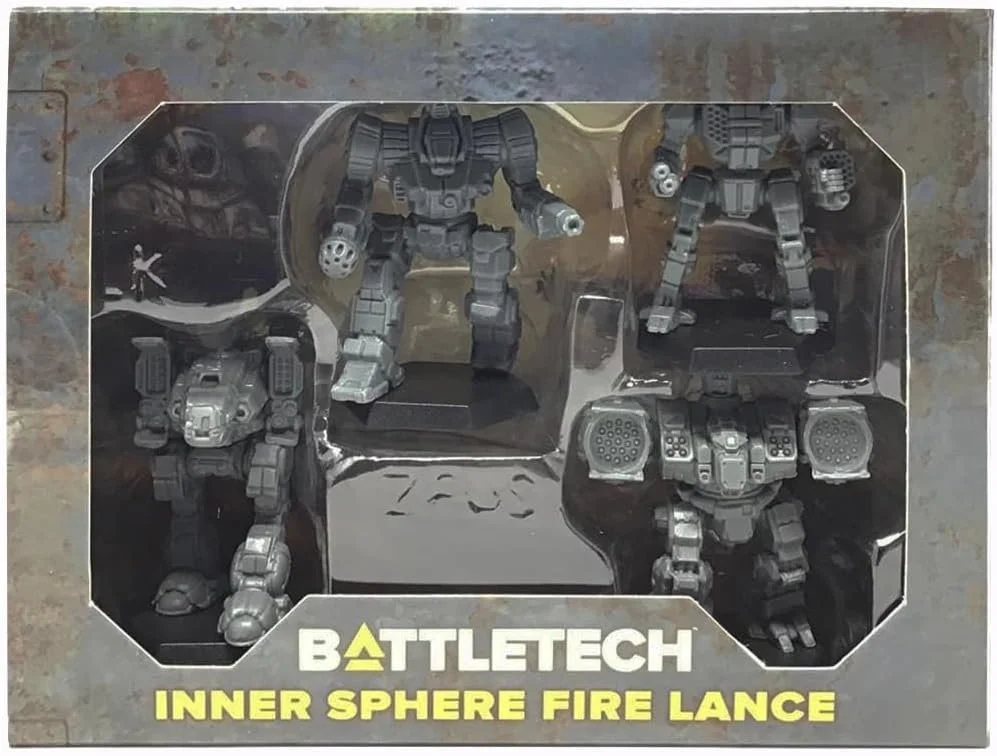

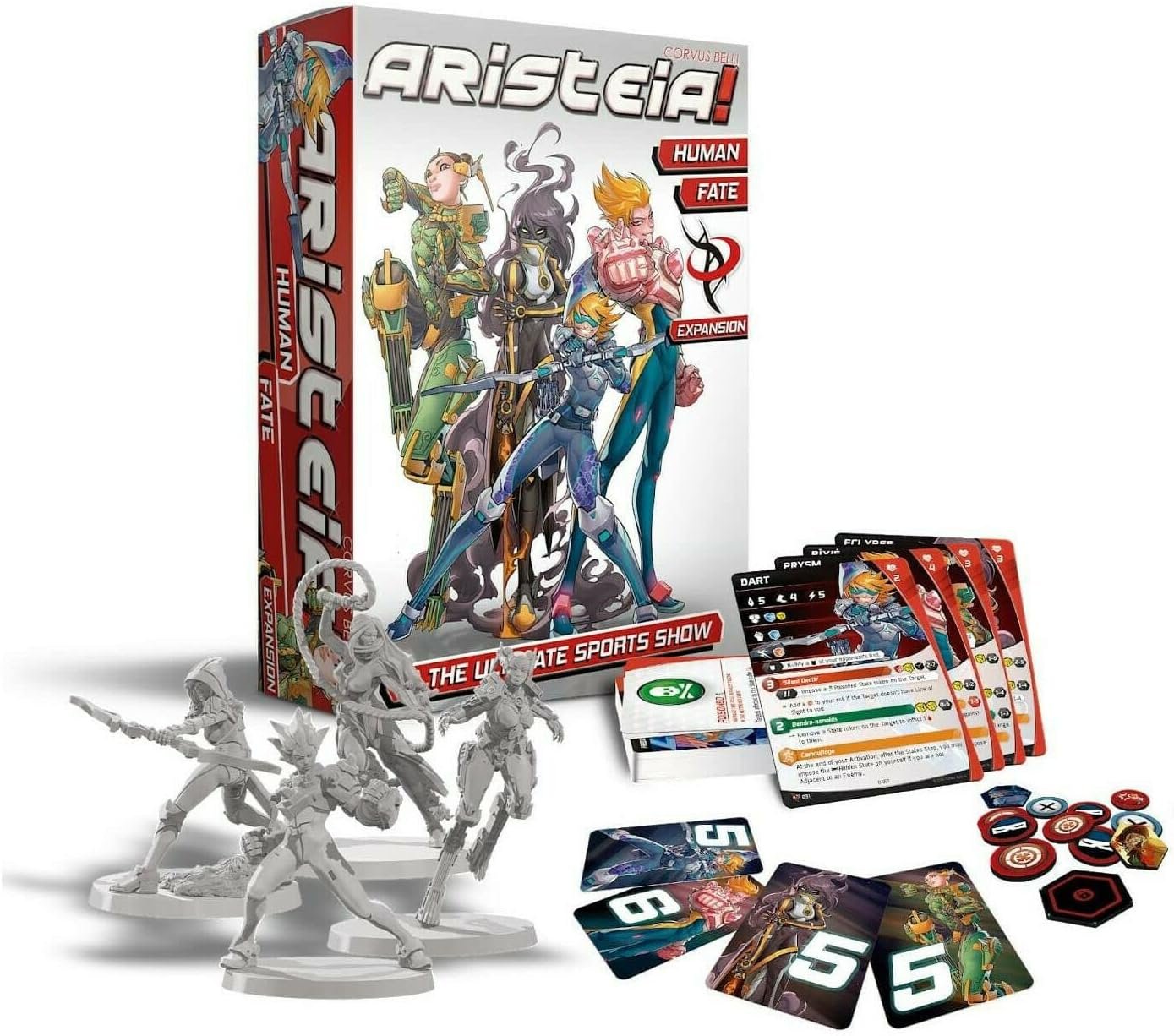

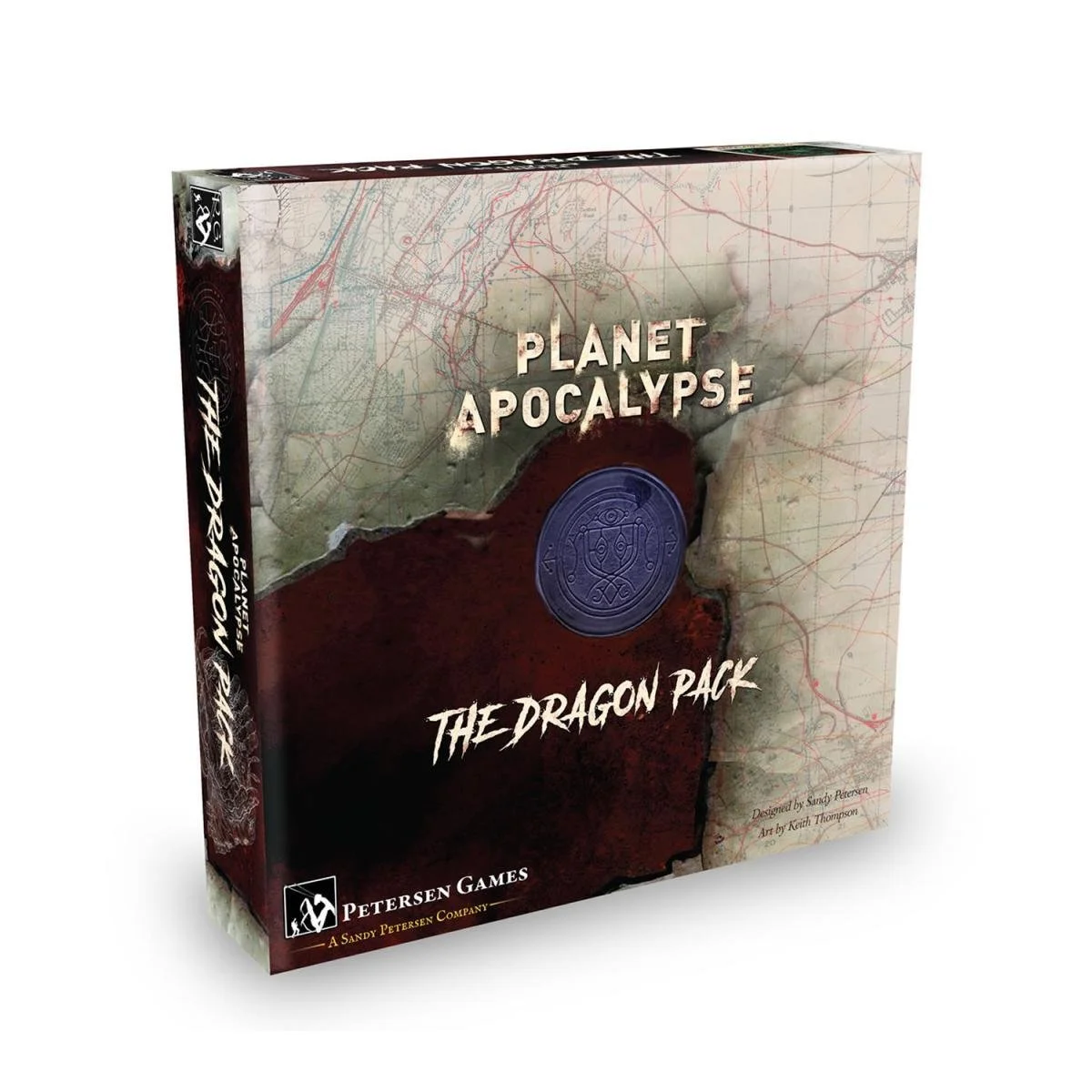

Liya International is a full spectrum project management and manufacturing service for the hobby, toy, print, board game industries, and more. With over 27 years of experience, Liya has helped hundreds of projects cross the finish line and thrill end-users worldwide. Our team is invested in your project, and committed to shared success.

Liya provides a true one-stop-shop for all your design, prototyping, project management, and manufacturing needs. We also are proud to announce the completion of our factory expansions for the start of 2020, bringing 13 injection mold machines in-house. The competitive advantage is for you, and your project, a professional technical team with direct control over your project, and maintaining quality assurance and more accurately managing timely delivery. No more waiting on a 3rd party.

At Liya, we work to bring our customers into a family of true partners. We will work closely with you at the beginning of the design stage, through the completion of your project. We bring a decade of experience in industry-standard processes and exposure to all manner of design solutions to literally bring your dreams into reality. Whether it is sourcing sculpting and paintwork, improving quality, reducing cost, or organizing packing for your latest Kickstarter, Liya is ready to work with you.

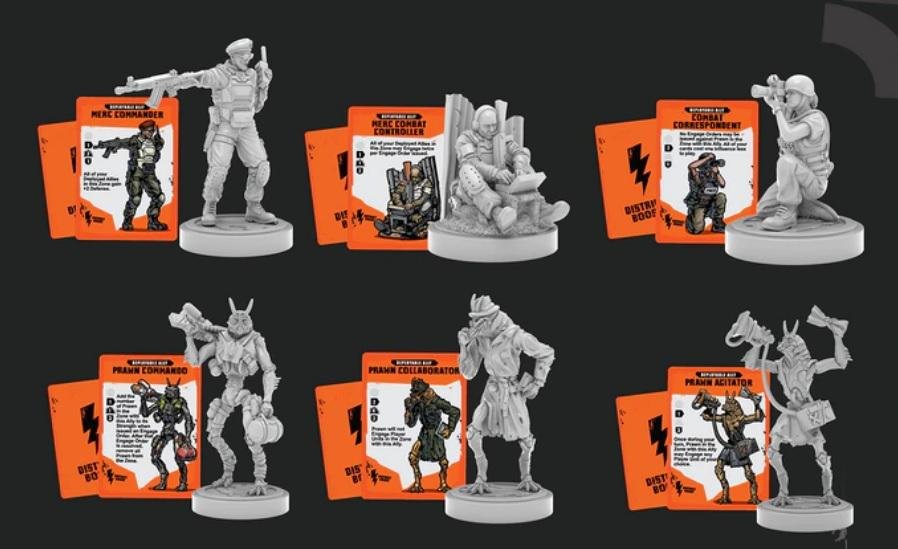

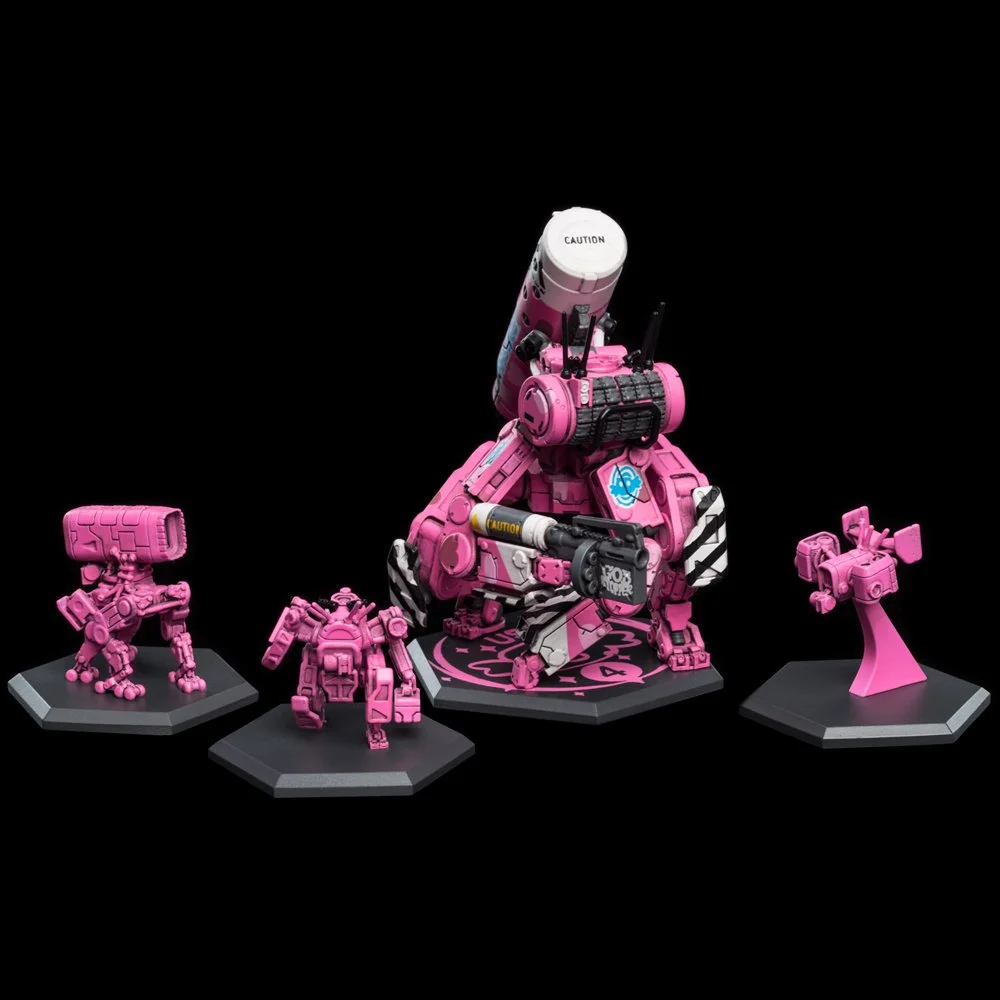

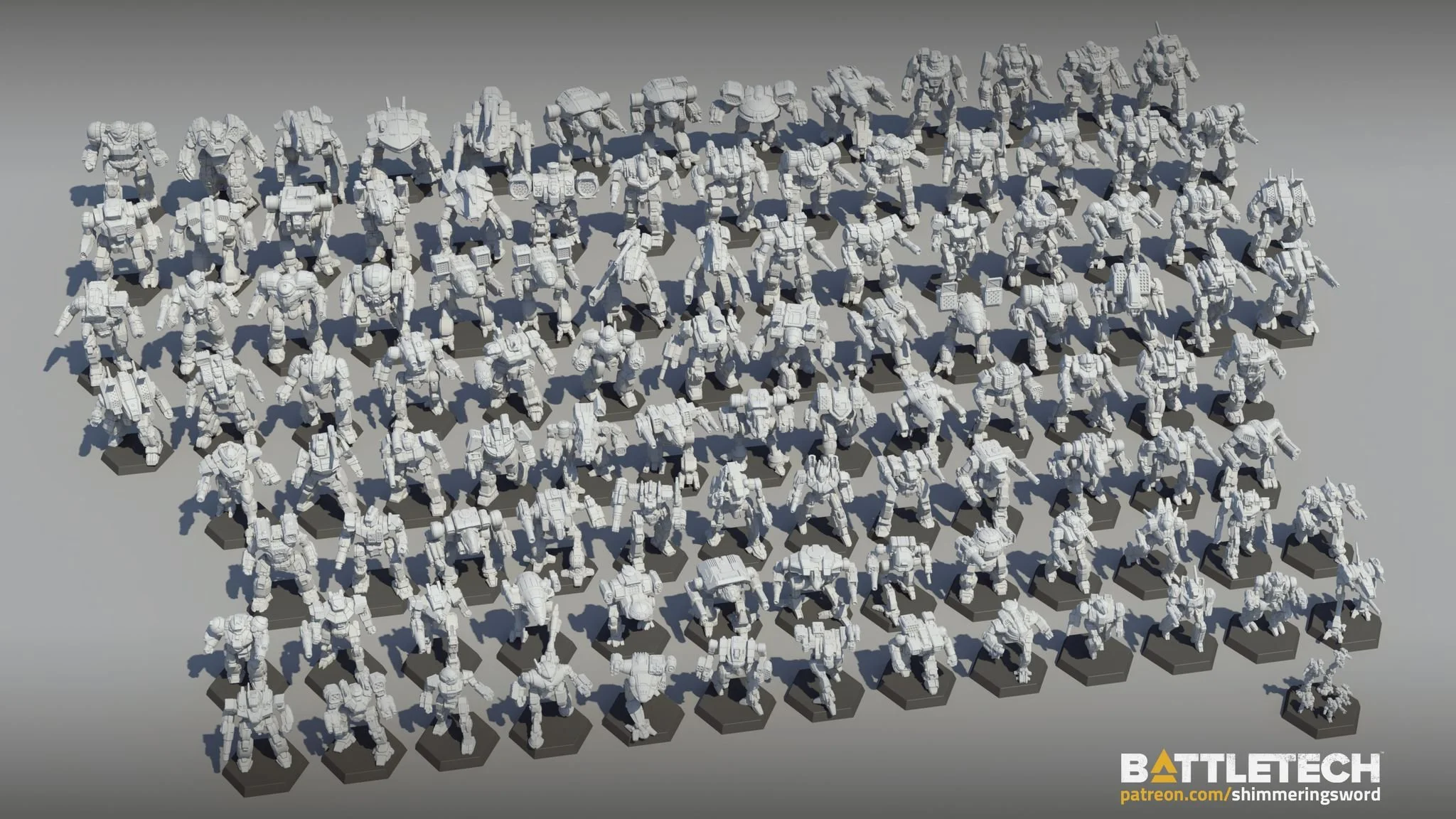

Liya International assembles millions of models each year for publishers and partner factories worldwide, operating as a full-service OEM manufacturer with robust, scalable facilities. Our vertically integrated production environment allows us to adjust labor and internal resources quickly to meet changing capacity demands without compromising quality or timelines. For plastic production, we own and operate our own tooling department, injection molding machines, and dedicated assembly lines, giving us complete control over every stage of manufacturing. To further streamline production and ensure consistent finishes, we also offer in-house painting, allowing projects to move seamlessly from mold to final assembly under one roof.